The steel material phosphating process has the purpose to produce a thin and compact conversion layer which is strongly anchored to the surface in order to facilitate the cold deformation or the further drawing operations.

There can be different types of phosphating (with Zn or Mn). After phosphating, it is necessary to cover the treated surface with a lubricating layer. Before the process it is essential for the surface to be perfectly clean, without any oil, grease, metallic oxides and acidity. This is usually guaranteed by using chemical pickling operation (with H2SO4 or HCl) and subsequent vigorous water washing or by means of a shot-blasting operation.

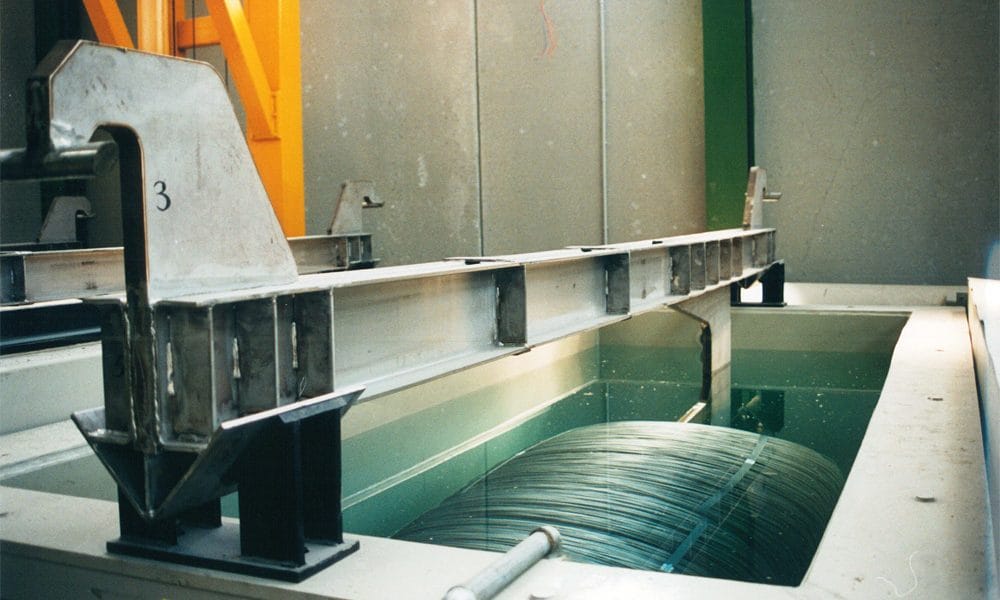

The phosphating process is generally carried out by dipping of the material into a hot solution tank and the dipping time depends on the required layer thickness.

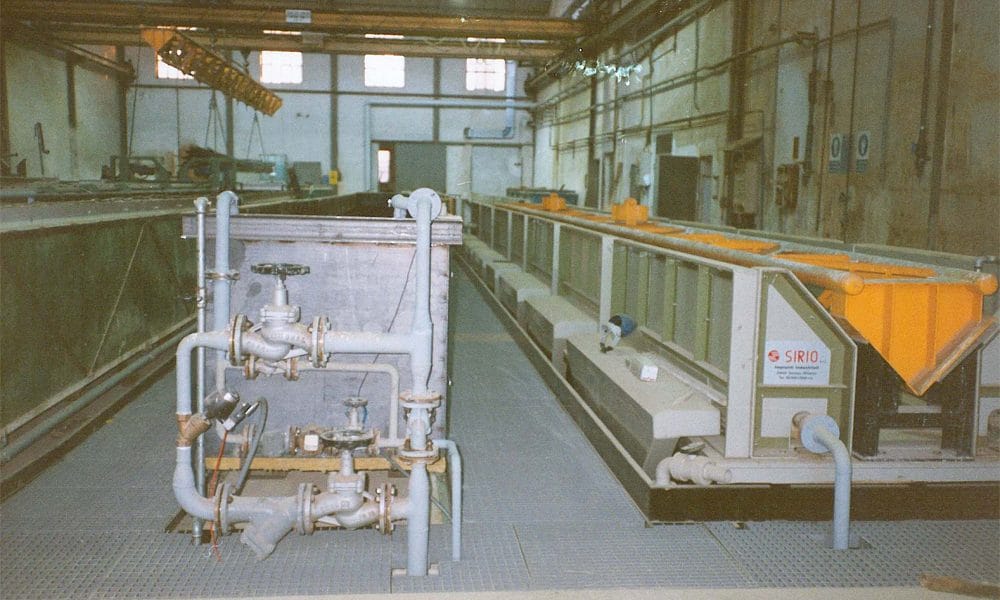

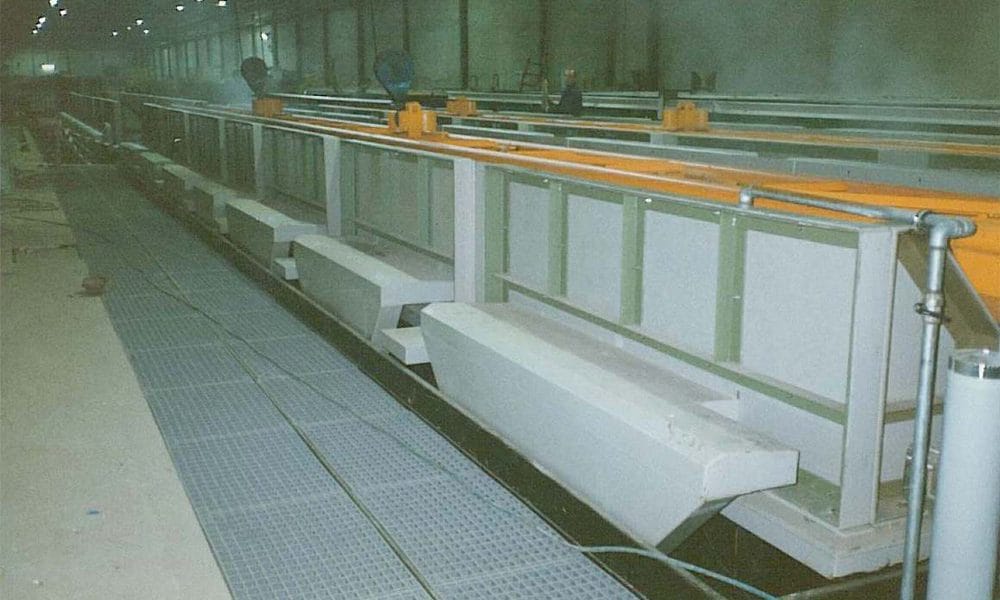

Phosphating and pickling plants

The Phosphating Process is applied to the tubes, wire rod, small parts, bars and profiles sectors.

These plants are designed according to different factors:

- Type of materials to be treated

- Required productivity

- Degree of automation

- Available areas

- Budget

On the basis of these factors, SIRIO together with the Customer choose the best type of layout and management system (manual, semi-automatic or automatic).

Support in all the phases of the project

SIRIO, thanks to the experience gained in this field, provides to the Customer the necessary support in all phases of the project:

- Feasibility study and investment evaluation

- Detailed design and engineering

- Construction

- Erection or assistance to erection

- Start-up

- Training of Customer operators